Chicken Cage Layered 4 tiers “H” Type 192 Birds

$168.00

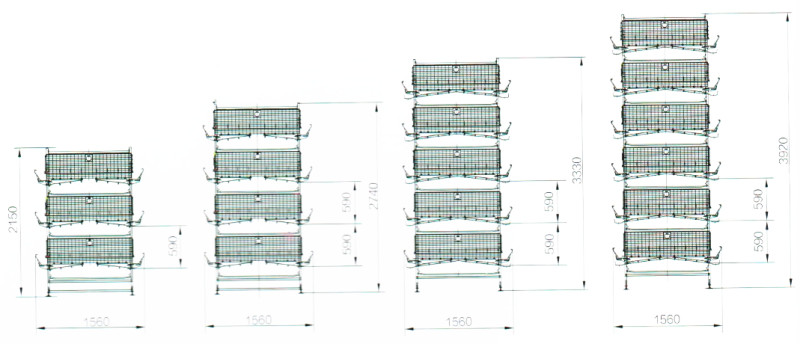

Chicken cages layered 192 Birds H type, cages dimension is: 1900*1560*2740mm; number of accommodation will be 6 birds , it has 32 cells, 192birds capacity per

描述

Chicken Cage layered 4 tiers “H” type 192 Birds

►Chicken Cages Layered 4 tiers H type 192 Birds ,

| Item | XFH4-192 | Area/cell | 2820 |

| Tiers | 4 | Area/chicken | 470 |

| Chicken/cell | 6 | Cell Dimension cm |

47*60*33/40 |

| Cell/set | 32 | food chicken cm |

7.83 |

►Performance of Chicken Cages layered:

- The four layers of stacked layer cage bracket is made of cold plate rolling galvanized, and the food trough is made of white plastic steel, including adjustment plate and joint;

- Cage mesh composite hot-dip galvanized production durable;

- The surface of the cage wire of laying hens is smooth without cracks, scratches and other harmful defects. After the cage net is formed, it can effectively prevent the injury of chicken feet and prevent the occurrence of staphylococcus caused by the infection of chicken feet caused by steel wire cracks.

- Easy assembly, feeding convenient, easy management, save space, effective prevention of infectious diseases, improve the survival rate of chickens;

- Reduce labor cost, realize full automatic control of feeding, feeding, drinking water, clean feces environment, greatly reduce labor intensity of workers, and save labor costs;

- The investment province adopts the cascade culture equipment under the same scale of culture, with high feeding density, saving land and high intensification degree

Description of Chicken Cages Layered 4 tiers“H”type 192 Birds

►Chicken Cages Layered mesh :

- Material: Q 235 high quality unannealed steel wire

- Bottom of cage has 7 ̊ slope, the angle of inclination is reasonable, to ensure that the eggs roll gently and smoothly

- Weaving process: First welding and then bending

- Surface treatment: Hot dip or electroless galvanizing

- Advantages: smooth surface, good elasticity, high strength, low egg breaking rate and so on.

►H frame of Chicken Cages Layered:

- Material:U Type rectangular tube with hot galvanized ,Angle Iron or 6 mm thick steel flat

- Weaving process: cutting, stamping, bending, welding, forming.

- Advantages: strong, sturdy and smooth

- Years of use: 20-25 years

►Water drinking line of Chicken Cages Layered:

- Highly precise stainless steel Ball

- High sensitivity ,360 ̊ Active sealed stem

- No leakage guarantees dry of chicken manure

- Installation, disassembly,convenient and cleaning is easy no need for glue and bonding

- 25# PVC round pipe

►Feeder trough for Chicken Cages Layered:

- Material:PVC plastic or hot galvanized steel

- Color: white ,green ,red or you request

- Plastic food trough : raw polyethylene materials, super toughness, with anti-fall, anti-pressure, anti-aging

- Characteristics: durable, transport does not occupy the place, will not damage.

- The design of the long groove edge of the feeder though is very good, which reduces the waste of the chicken food.

►Front water Supply for Chicken Cages Layered:

- In front of poultry house there is a filter for water cleaning , a medicator and water meter

- Pressure regulator Concentration of chemical feeder is adjustable and the water meter is numerable

- The pressure reglator it can adjust pressure at the outlet and has a recoil function

Comparative analysis Chicken Cages Layered “A” frame types

Standard layout of Chicken Cages Layered 192 birds 4 tiers “H”type

- Unit Size:1900*1560*2740 mm

- The use of 4 rows by 4 tiers 192 birds “H” type

- The chicken house measures 100 meters long

- 13.5 meters wide

- 3.5 meters height in the room

- 47 units per row

- Breeding number of chickens is 36096 birds

►Related chicken cage layered equipment

Use cooperatively H frame chicken cage layered equipment produced by Xiangfa Company, it can realize the automatic feeding control system, the egg collection system, the automatic control of the scraper manure-clearing system, the operation is convenient, the labor productivity is improved, the economic benefit is high, and it is suitable for large-scale Laying hen culture

The following machine should be customer request:

►Packing and delivery of chicken cage layered:

- The bottom and top cage wire mesh make 6 pcs one bundle, The partition cage wire mesh make 12 or 15 pcs one bundle,the doors make 12 pcs or 60 pcs one bundle but they are bulk no package.

- The Frame stands make five five pcs per bundle but they are bulk no package.

- Some fittings are in plastic bags or cartons

- LCL: first packed with plastic film then shipping by pallets

- FCL: The cage mesh and frame stand make by bundles ,and the accessories packing by plastic bag or cartons,

- The chicken equipment by pallets.

- Others packing and the poultry equipment according to customer requirement

- Battery chicken cage transportation

►Layered chicken egg cages are generally divided into three layers and four layers.

1. Stepped egg cage, simple and durable;

2. Chicken cage net and bottom net encryption, effectively prevent the chicken from licking the anal phenomenon, reducing the egg breaking rate and laying chicken fatigue syndrome;

3. The whole set of products adopts hot-dip galvanizing process and has long service life; Q235 material has large elasticity and is not easy to bend;

4. The thickening structure of the front mesh wire is firmer, the structure is reasonable, and the energy consumption is low;

5. Unique cage door design, the cage door space is larger, the position of chicken feeding can be arbitrarily changed, which effectively solves the crowding of chickens when eating, ensuring that the birds eat more evenly;

6. Using conveyor belt type to clear the feces, the chicken manure is dried into granules, reducing environmental pollution, and the high utilization rate of chicken manure;

7. Many customers at home and abroad use it with excellent results.

►The chicken cage layered egg cage is divided into three layers and four layers.

1. Laminated hen cage cage mesh mesh combination, hot galvanizing production is durable.

2. The bracket is made of cold plate rolling forming galvanized, the trough is made of white plastic steel, including adjusting plate, including joint, plastic mat mesh aperture Q15mm.

3. Egg cage cage wire surface is smooth, no cracks and scratches and other harmful defects.

4. After the chicken net mesh is formed, it can effectively prevent the injury of the foot of the chicken and prevent the occurrence of staphylococci caused by the infection of the foot of the chicken due to the wire laceration.

5. Easy to assemble, easy to raise, easy to manage, save space, effectively prevent infectious diseases, and improve the survival rate of chickens.

6 Reduce labor costs, achieve full automation of feeding, feeding, drinking, cleaning, and environmental control, greatly reducing the labor intensity of workers and saving labor costs.

评价

目前还没有评价

评价

目前还没有评价